"Combining our experience with an understanding our customer’s needs is a formula that has brought us a lot of success at True Precision. We form partnerships with our customers with the intent of reducing overall costs and delivery times while increasing quality by utilizing the latest technology in machine tools, software and processes.""We manufacture parts from a variety of materials. Many of our customers use titanium in their products and as a result we are proud of the fact we have become industry experts in manufacturing parts from titanium along with other metals."Todd Ackert, President, True Precision Machining

Production/Contract Machining

We offer low to high volume production runs. We utilize state-of-the-art equipment maximizing production and optimizing cycle times along with lights out manufacturing makes us able to offer our customers the most efficient means of production. Our process utilizes the following equipment: CNC Milling (both horizontal and vertical), palletized and robotic, CNC turning with milling capabilities. 6 axis Wire EDM with robot.

We have multiple long-term agreements (LTA’s) that ensure consistent pricing and delivery that our customers count on. Offering safety stock allowing for fluctuations in demand.

Materials We Work With:

- Titanium

- Stainless Steel

- Controlled expansion alloys

- Aluminum

- Coppers

- High Chrome alloys

- High Nickel alloys

- Plastics

- Castings

- Extrusions

- Tungsten

Industries We Serve:

- Aerospace

- Medical

- Defense electronics

- Defense armament

- Communications

- Deep sea enclosures

- Space components

- Hermetic enclosures

- High vacuum enclosures

- Cryogenic components

- Nano technologies

Prototype Manufacturing

Using our modern multi-axes CNC equipment our technicians can produce prototype parts in a timely manner reducing your time from inception to market. We take pride in our ability to collaborate with customers to turn their prototypes into full scale products by ensuring the CAD model reflects the blueprint and recommending difficult to machine and/or “over tolerance” features for DFM improvement.

Assembly/Turnkey Manufacturing

We offer more than just Production and Prototype manufacturing. Our Turnkey solution may be exactly what you are looking for. We have found that many of our customers rather not buy just individual parts. Let us take care of that for you.

We can:

- Manage your process requirements

- Analyze your design/specifications – See Design for Manufacturing

- Manufacture needed parts

- Work with your and/or our vendors, if applicable

- Assemble the product

- Test and document your assembly or sub assembly based on your specifications

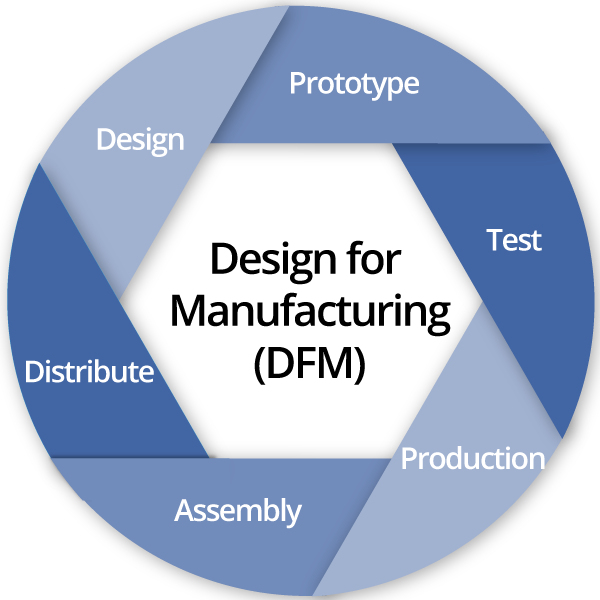

Design for Manufacturing (DFM)

Design for Manufacturing (DFM) also known as Design for Manufacturability, is a design practice that focuses on the reproducibility and manufacturing process of a product. It allows potential problems to be fixed as well as an analysis of each component of the design where costs can be reduced. Several factors can affect the cost and manufacturability such as type of raw material, the dimensional tolerances and secondary processing such as finishing

Save Time and Money

Our many years of expertise enable us to offer our customers ways to optimize their designs saving them time and money.

As part of the DFM process, we analyze your design for:

- Material Type – Help you determine what materials offer the best machine ability vs cost for your application.

- Material Form – The size and shape of the component may determine which form of material must be used.

- Dimensional Tolerances – Analyze the geometric tolerances for each feature and higher level assembly to determine if any cost saving can be realized with tolerance adjustment. Don’t pay for precision where you may not need it.

- Design and Shape – Machining is a subtractive process, the time to remove the material is a major factor in determining the machining cost. The volume and shape of the material to be removed as well as how fast the tools can be fed will determine the machining time.

Inventory Management

Lean Manufacturing

Our ongoing production is conducted using lean manufacturing practices. Partnering with our customers we can obtain the optimum equipment for their production needs.

Kanban (Con-Bon) and Just-In-Time (JIT)

We have experience working with customers who utilize Kanban and JIT methodologies to efficiently manage inventory stock and meet demanding production schedules.

Quality Control

Beyond Inspection

Our dedication to quality goes beyond just inspection. We believe in building quality into each manufacturing process not just measuring parts at the end.

We utilize multiple methods of controlling quality including but not limited to:

- Statistical process control

- 1st article inspection

- Process control sheets

- Manual and automated CMM equipment to inspect the most complex parts with surfaces and profiles

Our Goal is to exceed all quality expectations by continually improving the quality of the products we manufacture while meeting the requirements of our customers.

TPM Software

Enterprise Software

TPM employs state-of-the-art software such as Vericut enabling us to reduce or eliminate the process of manually proving-out NC programs. It reduces scrap loss and rework. The program also optimizes NC programs in order to both save time and produce higher quality surface finish. This and other software gives us the flexibility to handle changing customer needs and job schedules. Above you can see some of the various software and system partnerships we use to remain competitive in our market.